AIC Can Help Add Value to Your Product or Project With Our Industry Expertise, Project Review, and New Project Development

How Can AIC Be a Development Partner?

Why Is AIC a Partner and Not Just a Supplier?

Why Should I Upgrade or Automate My Current System?

Can You Help Me Develop a Custom Solution?

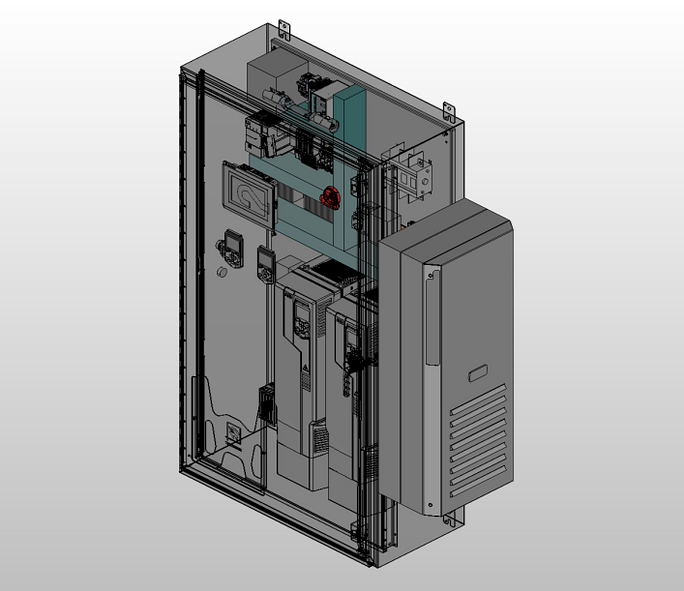

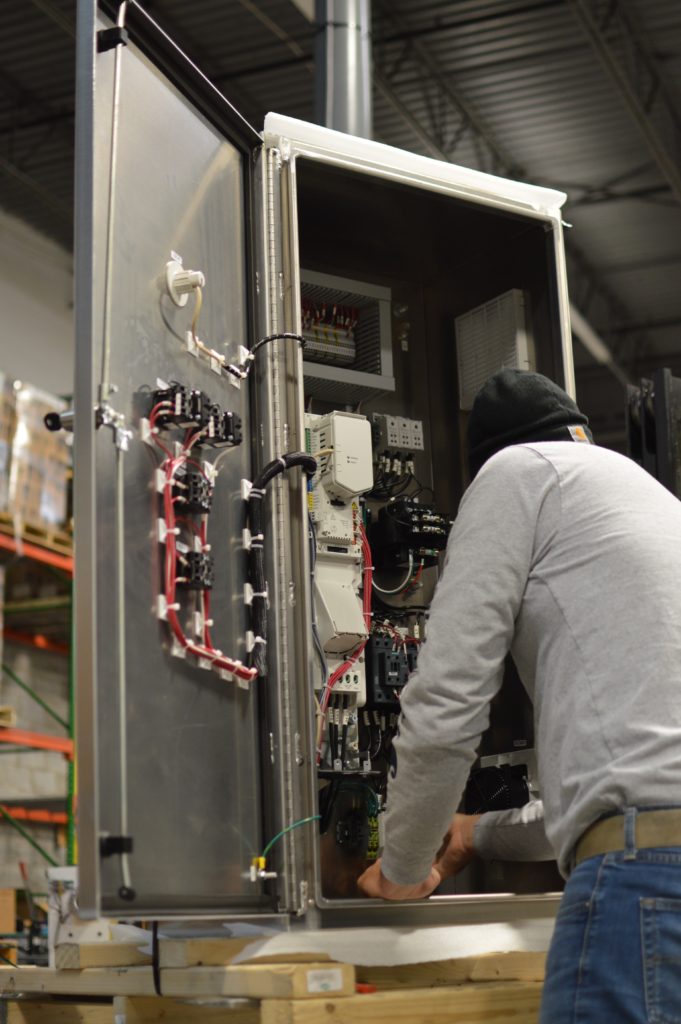

At Applied Industrial Controls, Inc., we have a thorough understanding of our customers’ business, which is why we are able to develop custom automation solutions that are among the best in the industry. Our experts have deep knowledge of regulatory issues, best practices, and trends in a variety of different industries. We are known for providing high-quality products and technical proficiency and have a proven track record when it comes to improving productivity and mitigating risks in projects involving custom control panel manufacturing. We offer a full range of consulting services that include:- Project Management – We can analyze any system requirement and provide process definition, system development, product development, and new feature development.

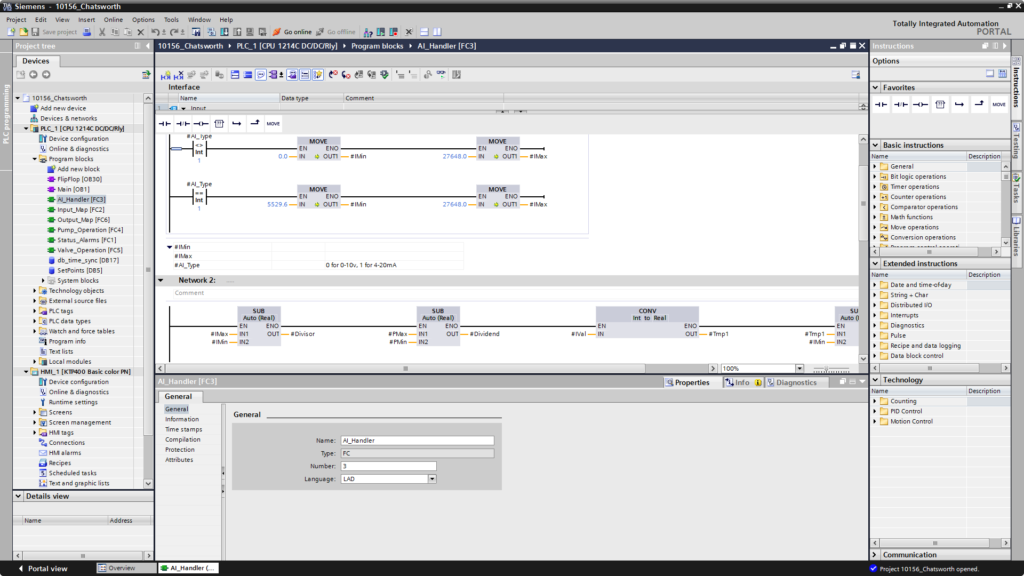

- Application Design – Our subject matter experts work closely with clients from initial concept through development and testing until the application ideally meets your needs.

- Training – Our engineering team has over 150 years of automation experience, over 70 years of production experience, and an average customer relations record of over ten years. With this experience, our trained staff will educate your team and build a long-term professional relationship.

- Troubleshooting and Diagnostics – We can diagnose small to complex issues and provide the solutions you need.

How Can AIC Be a Development Partner?

When you work with Applied Industrial Controls, Inc. as a development partner, you can feel confident that we will provide full automation solutions for your equipment or production line. We can analyze and evaluate your current operational methodologies and provide you with the best solutions that will optimize operations. AIC provides an unbiased consultation with no hidden agendas.

Some of the areas where we can help with development include:

- Project Scope Identification and Cost – Initially, it can be difficult to determine the scope and details of a new project. With our experienced staff, we can help with this as well as execute the scope to successfully achieve a completed project that is on time and on budget.

- Project Execution and Timelines – Accurate scheduling and comprehensive execution will save time and money. You can trust that while collaborating with AIC, there will be minimal issues that can cause project delays and incur unnecessary costs.

Improve Business Development – While AIC is working to optimize and automate your operations, you can concentrate on your core business and future business goals. - Risk Mitigation Strategies - Avoiding risk is the best way of dealing with issues that can derail your project. We help with risk mitigation at the onset.

Get in touch with us today to discover how we can work together.

Why Is AIC a Partner and Not Just a Supplier?

Our goal at Applied Industrial Controls, Inc. is to understand your business and develop lasting solutions that help you reach your goals. We want to educate you on our capabilities so that we make the ideal solution together to have the most efficient, cost-effective, and user-friendly operations systems. We also want to support the systems we implement by being available anytime; building long-term, quality relationships and strategic partnerships with our clients.

We provide comprehensive, custom solutions to OEMs, maintenance and operations personnel, as well as machine integrators in a range of industries. Some of these solutions include improving custom control systems with features that reduce costs, adding new integrations. These consist of SCADA or machine interlocks, operational analysis, production support, and much more.

Get in touch with us today to discuss how we can build a successful and long-term partnership.

Why Should I Upgrade or Automate My Current System?

In a production or manufacturing facility, automating systems is extremely beneficial to overall operations efficiency. It enables real-time information from multiple pieces of machinery to be available in a single database where operators can analyze it locally or remotely. This allows operators to more quickly identify and focus on errors, issues, or failures that could result in production delays or catastrophic failures.

Automation allows compatibility with smart devices and IIoT. IIoT is basically when real-time data from machines is connected through a network and is recognized with Industry 4.0.

Get in touch with us today to request an on-site visit or phone call to get the process started.

MANUFACTURERS CERTIFICATIONS